Custom UMS test tanks

Our ultrasound test tank systems are custom built to suit the end user’s requirements and additional features can be included.

Our ultrasound test tank systems are custom built to suit the end user’s requirements and additional features can be included.

If you have any specific questions about this product, please contact us.

Precision Acoustics ultrasound test tank systems are custom built to suit the end user’s requirements and additional features can be included. These links offer more details on UMS software and acoustic parameters, with these UMS downloads also available.

| Motorised axes | Standard systems have 3 motorised axes but we have made systems with 10 motorised axes. The axes are fitted with linear encoders to ensure repeatable positioning. Limit switches are fitted to all axes. |

| Scan step size / resolution | Linear encoders give positional accuracy and linear repeatability ± 0.005 mm over length of travel and system resolution 0.001 mm working speed 20 mm per second and fitted with user adjustable limit switch and emergency stop control. |

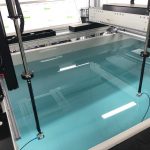

| System geometry | UMS can be configured either “horizontally” or as a “shoot down” system for open back transducer testing. |

| Frequency range / maximum tank size | Frequency range: this will depend on the physical size of the test tank and acoustic lining. Please contact us for accurate information on tank size requirements for your working frequency. Standard tanks are 1 m x 0.5 m x 0.5 m which are suitable for measurements in the range 0.5 MHz to 60 MHz. We have supplied tanks up to 3 m x 1.5 m x 1.5 m which are suitable for measurements above 50 kHz. Depending on the physical size of the water tank it can be bench mounted or positioned at a reasonable working height. |

| Programming language | All software is written in LabVIEW 2021 and later. |

| Automates planar scanning routines | The software integrates the positioning system, oscilloscope and PC for automated data capture and storage. |

| Data processing | The included post processing software enables the calculation of standard acoustic reporting parameters from the acquired data. |

| Customised software | We can customise the software for customer specific applications and equipment. The software integrates with Keysight Technologies oscilloscopes (DSO-X 3000 Series) but we can change the software to suit other oscilloscopes when required. |

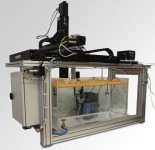

The image opposite is a system supplied by Precision Acoustics to the Biomedical Ultrasonics and Biotherapy Laboratory (BUBL) at the University of Oxford.

Ultrasound measurements rely on the ability to measure accurately the acoustic field. The UMS4 system has three motorised axes (x,y,z) each capable of a 6-micron repeatability. The system supplied complete with an electronic control module and a PC with preloaded UMS software. The software is optimised for interaction with Keysight Technologies DSO-X 3000 series oscilloscopes but the works with many other modern oscilloscopes.

Options include an additional “rotational axes positioning device” to facilitate accurate alignment of the transducer’s acoustic axis with the hydrophone; water conditioning system; hydrophone and transducer mounts.

To simplify purchasing for our clients we can also supply all power amplifiers and function generators.

If you would like more information about this product, please get in touch by phone, email or enquiry form.

Alternatively complete our enquiry form below.

Telephone:

Email:

Precision Acoustics Ltd

Hampton Farm Business Park

Higher Bockhampton

Dorchester

Dorset DT2 8QH

United Kingdom

© Copyright Precision Acoustics Ltd. 2025

Registration number: 02466435

VAT number: GB529840128

Feedback | Terms & Conditions | Privacy Policy | Site by Click 71

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |