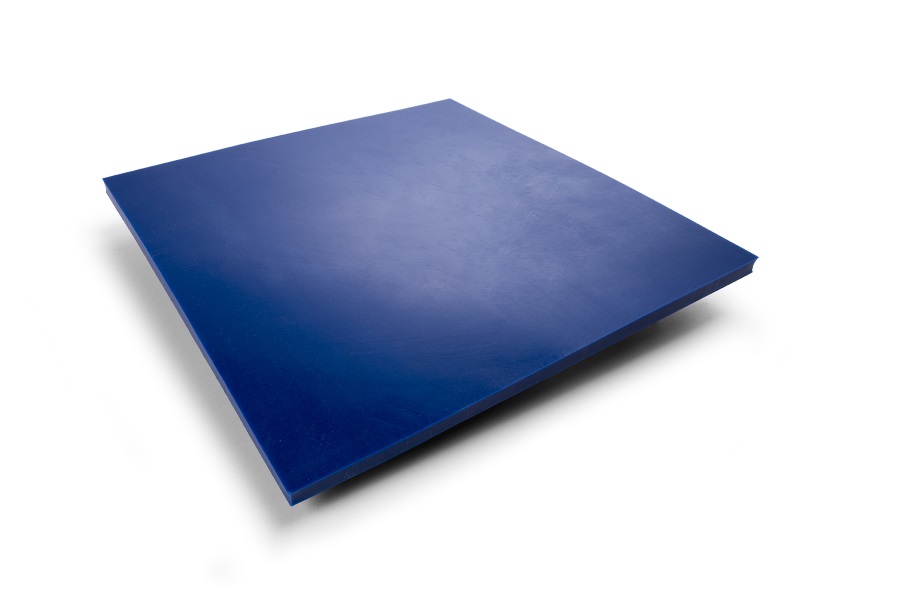

Aptflex F28

Part of a family of high frequency acoustic absorbers and provides the most cost effective method of absorbing unwanted ultrasonic reflection and acoustic isolation.

Part of a family of high frequency acoustic absorbers and provides the most cost effective method of absorbing unwanted ultrasonic reflection and acoustic isolation.

This product is available to buy direct through our secure online shop.

Acoustic output measurements or ultrasonic testing, in general, can be strongly affected by reflections or echoes from test tank walls. This is particularly true for long tone burst or continuous-wave ultrasonic applications. To overcome this, test tanks should be coated with linings which must be of low ultrasonic reflection yet highly absorbent to ultrasound. NPL’s material has been designed specifically to meet this requirement.

Its simple design, being a single layer, ensures that the material is the cost-effective solution for coating large areas such as the walls of an ultrasonic test tank.

High insertion loss, approximated by 30 dB/cm/MHz. Insertion loss at frequencies greater than 2 MHz is in excess of 60 dB. This exceeds the dynamic range of the measurement and hence no more detailed data is available.

If you would like more information about this product, please get in touch by phone, email or enquiry form.

Alternatively complete our enquiry form below.

Telephone:

Email:

Precision Acoustics Ltd

Hampton Farm Business Park

Higher Bockhampton

Dorchester

Dorset DT2 8QH

United Kingdom

© Copyright Precision Acoustics Ltd. 2025

Registration number: 02466435

VAT number: GB529840128

Feedback | Terms & Conditions | Privacy Policy | Site by Click 71

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |